A Horizontal Packaging Machine is an automated packaging equipment characterized by its core "horizontal placement" structure. It is mainly designed for irregular or large-volume materials such as long strips, cylinders, and rings. It completes the packaging process through horizontal wrapping, winding, sealing and other actions, and is widely used in industries such as building materials, hardware, chemical engineering, logistics, and auto parts. It solves the pain point that Vertical Packaging Machines are difficult to adapt to long-size and heavy-weight materials.

Core Working Principle

The working logic of a horizontal packaging machine revolves around "horizontal material conveying + circumferential wrapping", with the process as follows:

Material Positioning: The materials to be packaged are horizontally fixed on the equipment workbench through conveyor rollers, chains, or clamps to ensure no displacement during the packaging process.

Packaging Material Supply: The equipment automatically releases packaging materials according to requirements; some models can simultaneously achieve material cutting and positioning.

Horizontal Circumferential Wrapping: The rotating mechanism drives the packaging material to perform 360° circumferential movement around the horizontally placed materials, or the materials themselves rotate slowly in coordination with material conveying to achieve a "full wrapping" effect.

Finishing and Output: After wrapping is completed, the equipment automatically performs heat sealing, bonding, or cutting for finishing. Finally, the packaged materials are transported to the next process via the conveying system.

Advantages: Why Choose a Horizontal Packaging Machine?

Compared with vertical packaging machines and manual packaging, horizontal packaging machines have irreplaceable advantages in specific scenarios:

Strong Adaptability: It can handle long and heavy materials with a length of 1-10 meters and a weight of several tons, solving the problem of "material height limitation" of vertical equipment. It is especially suitable for packaging long profiles in the building materials and steel industries.

High Packaging Stability: When materials are placed horizontally, their center of gravity is lower. Combined with fixed clamps, they are less likely to topple during packaging, avoiding packaging damage or equipment failure caused by material displacement.

Balanced Efficiency and Cost: Fully automatic models can achieve a packaging speed of 10-30 pieces per hour, far exceeding manual packaging; semi-automatic models reduce equipment investment costs and are suitable for small and medium-batch production.

Controllable Packaging Effect: By adjusting parameters such as wrapping layers, film tension, and heat shrinkage temperature, different requirements such as "moisture resistance, scratch resistance, and anti-loosening" can be achieved. The film layer error of some high-precision models can be controlled within ±0.1mm.

Wide Compatibility: It can be matched with a variety of packaging materials and seamlessly connected with conveyors, weighers, and labeling machines in the production line, integrating into the automated production process.

Application Industries and Scenarios

The "horizontal adaptability" feature of horizontal packaging machines makes them essential equipment in multiple industries:

Steel/Non-Ferrous Metal Industry: Used for moisture-proof packaging of steel coils, aluminum coils, copper tubes, and stainless steel profiles to prevent oxidation and rust during transportation.

Building Materials Industry: Packages PVC pipes, aluminum alloy door and window profiles, and scaffold steel pipes to prevent scratches and deformation during handling.

Auto Parts Industry: Performs heat shrink packaging on long or circular auto parts such as auto half-shafts, drive shafts, and tires to improve product appearance and protection.

Logistics and Warehousing Industry: Horizontally wraps and fixes stacked cartons and palletized goods to prevent goods from scattering during transportation.

Hardware and Machinery Industry: Packages large gears, bearings, and machine tool accessories, taking into account both protection and warehouse space optimization.

Key Considerations for Purchase

When enterprises choose a horizontal packaging machine, they need to focus on the following points based on their own material characteristics and production needs:

Material Parameter Matching: Confirm the "maximum load" and "adaptable material length/diameter" of the equipment to avoid equipment overload or inability to accommodate materials.

Automation Requirements: Semi-automatic models can be selected for small and medium-batch production, while fully automatic models are required for large-batch assembly line production.

Packaging Material Compatibility: If heat shrink film is needed, select models with a hot air circulation system; if stretch film is used, confirm the "film width adaptation range" of the equipment.

Reliability of Core Configurations: Pay attention to the motor, rotating mechanism, and control system.

Manufacturer Services: Prioritize manufacturers that provide "customized solutions" and timely after-sales maintenance to avoid production disruptions due to equipment failures.

In summary, a horizontal packaging machine is a "specialized equipment" for packaging long and heavy materials. Its core value lies in the balance of "adaptability + efficiency + protection". With the upgrading of industrial automation, Intelligent Horizontal Packaging Machines are becoming the choice of more large manufacturing enterprises.

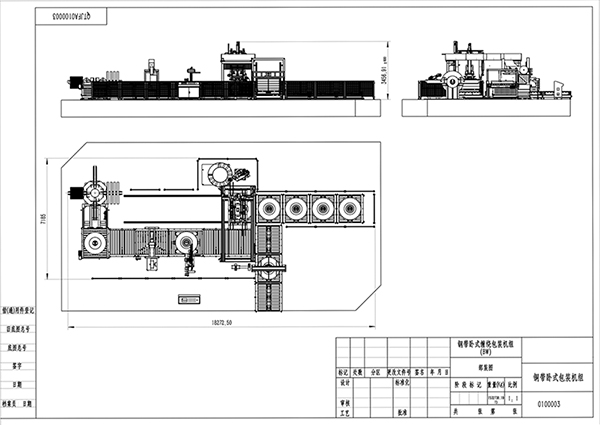

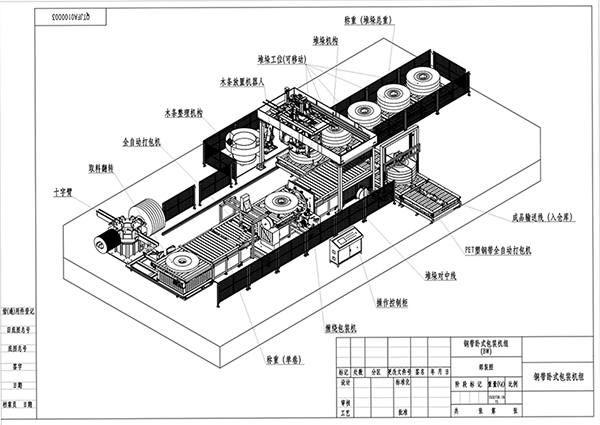

Shanghai Baoduan Machinery Manufacturing Co., Ltd. is located in Baoshan District, Shanghai, an international metropolis. It is a professional mechanical production enterprise engaged in equipment manufacturing and equipment R&D.

The company focuses on production equipment for metallurgical processing, as well as winding and packaging machine equipment for metal strips, pipes, profiles, tires, etc. Meanwhile, to solve problems such as product packaging and transfer in the actual production of metal strip processing enterprises, our company has also developed winding and packaging equipment for materials like metal strips, metal plates, pipes, and wires—including steel strip Winding Machines, copper coil winding and packaging machines, steel wire winding machines, steel pipe winding machines, horizontal winding machines, etc.—as well as industrial turning equipment such as 90-degree Steel Coil tilters, aluminum Coil tilters, Mold tilters, and 180-degree tilters.

Shanghai Baoduan Machinery Manu-facturing Co., LTD is located inBaoshan DistrictShanghai. Is a professional equipment manufacturing.

About

Copynght @ Shanghai Baoduan Machinery Manufacturing Co, LTD. All rights reserved

SitemapThis website uses cookies to ensure you get the best experience on our website.